Raw Wood Selection – All wood is hand selected and assembled for a natural color variation and grain pattern, which is based on the color of the finish you choose.

Raw Wood Selection – All wood is hand selected and assembled for a natural color variation and grain pattern, which is based on the color of the finish you choose.- Engineered Design of Components – All parts are designed to fit together and allow the flow of finish materials into areas of natural expansion and contraction, exemplified by the design of the inner profile on door rails and stiles and the center panel shape.

- Hand Sanding – All exposed surfaces of the doors, drawers, face frames, veneers, and mouldings are meticulously hand sanded before the finish materials are applied.

- Sap Staining – This is the initial stain coat that is applied to diminish the contrast in wood tone between the lighter sapwood and the darker heartwood.

- Toner Staining – This is an application of a base stain that creates the color tones of the finish.

- Sealer Coat #1 – A clear catalyzed sealer is applied over the base stain. This sealer coat helps to keep excessive moisture out of the wood, as well as maintain the natural moisture content in the wood.

- Oven Curing #1 – After the initial sealer coat, the product is oven cured at 120 degrees to activate the catalyst in the sealer.

- Sealer Sanding #1 – After the oven curing, the sealer coat is hand sanded to remove raised wood grain which develops during the sealing process. This hand sanding creates a smooth surface for our next finish application.

- Hand Staining – The application of additional stain creates the enhanced color by highlighting the grain of the wood to bring out its inherent beauty.

Optional Glazing – Light and dark pigments can also be applied at this step in the finishing process to create highlighting and accenting. - Oven Curing #2 – After the stain and glaze are hand wiped, the product is oven cured a second time at 105 degrees. The oven curing helps build the molecular bonds between the finish material applications.

- Sealer Coat #2 – A second, clear catalyzed sealer coat is applied to build on the depth, quality, and durability of the finish.

- Oven Curing #3 – A third oven curing at 105 degrees then takes place.

- Sealer Sanding #2 – The second sealer coat is then hand sanded to remove any additional raised wood grain, and to create a very smooth surface for the next application.

- Tack Cloth Cleaned – An inspection is performed on the product while the product is cleaned with a vacuum, forced air, and a tack cloth. This helps to eliminate particles of dust that may be on the product.

- Topcoat – Final application of a very durable catalyzed topcoat is applied. Customers have a choice of 10-Flat topcoat, 20-Matte topcoat or 45-Satin topcoat on all finishes.

- Oven Curing #4 – The product is oven cured a fourth time at 120 degrees, and completes the chemical bonding needed to produce the most durable finish in the industry.

- Final Inspection – A final inspection is performed on the finished product before moving into a holding area to allow the finish to further cure.

Finish Steps

Walnut Wood Specie

Select Alder Wood Specie

Red Oak Wood Specie

Quarter Sawn White Oak Wood Specie

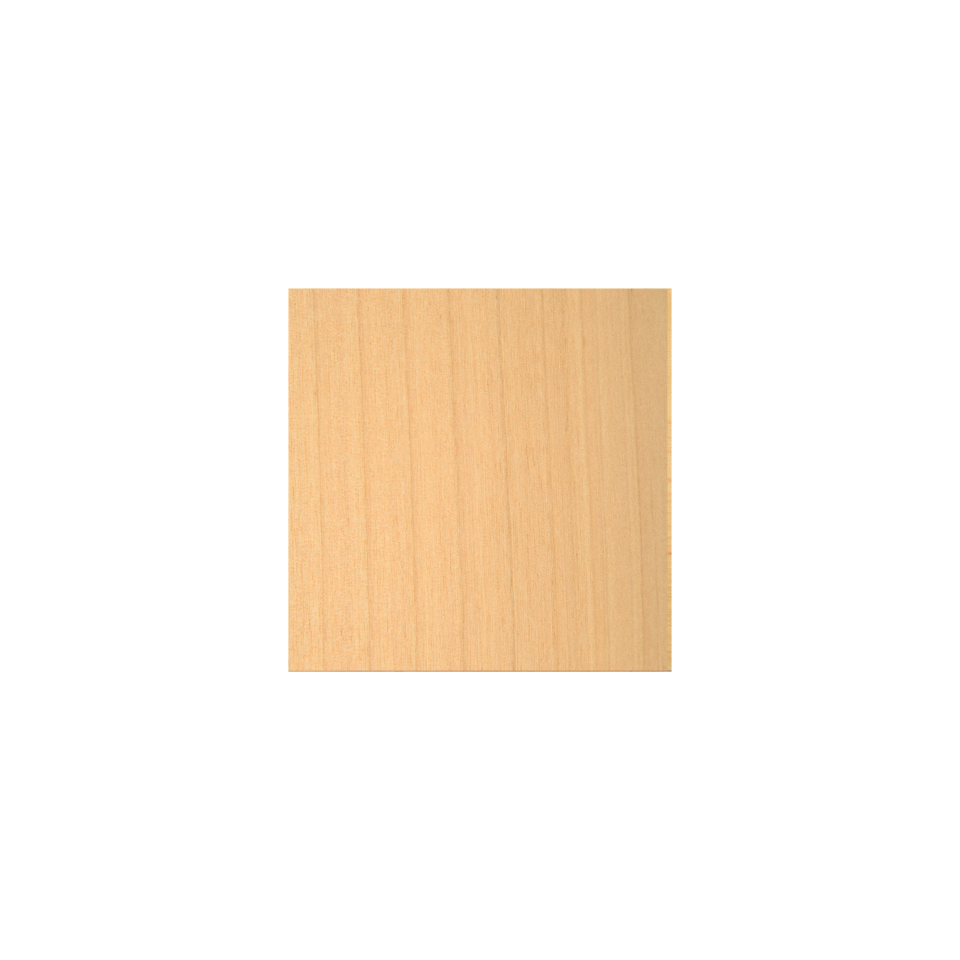

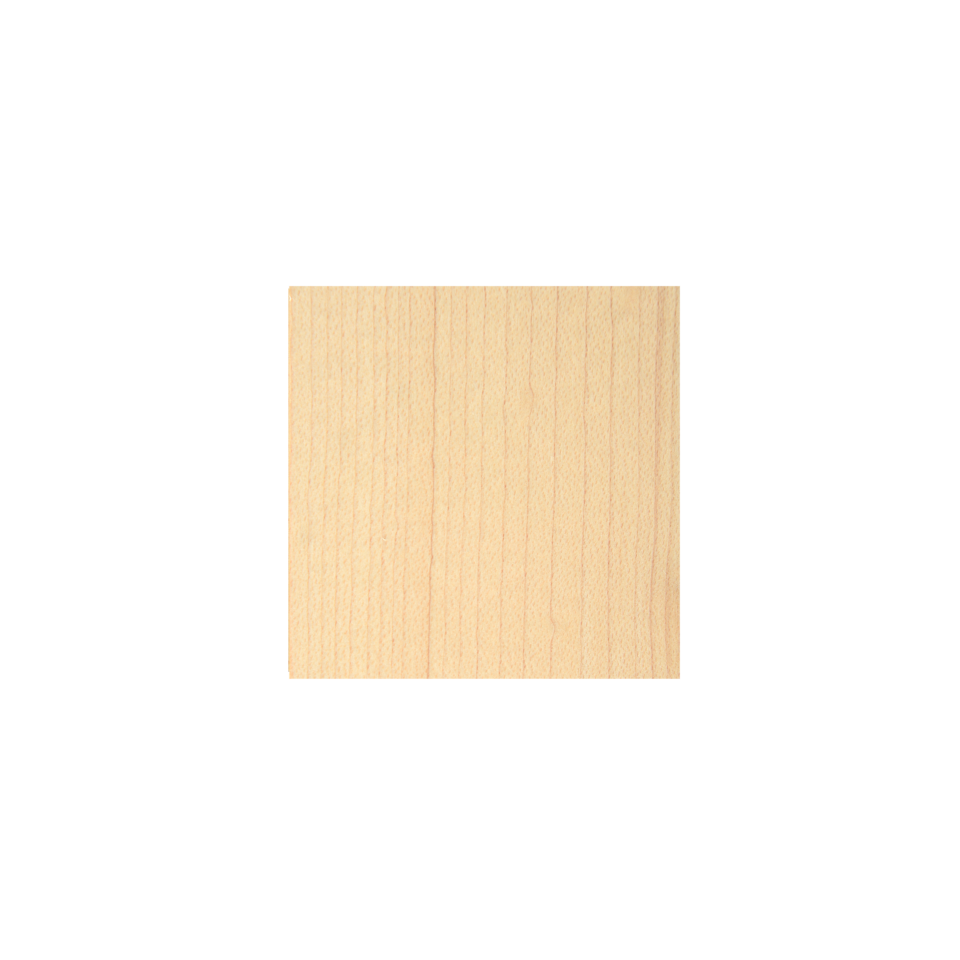

Paint Grade Maple Wood Specie

Maple Wood Specie

Knotty Alder Wood Specie

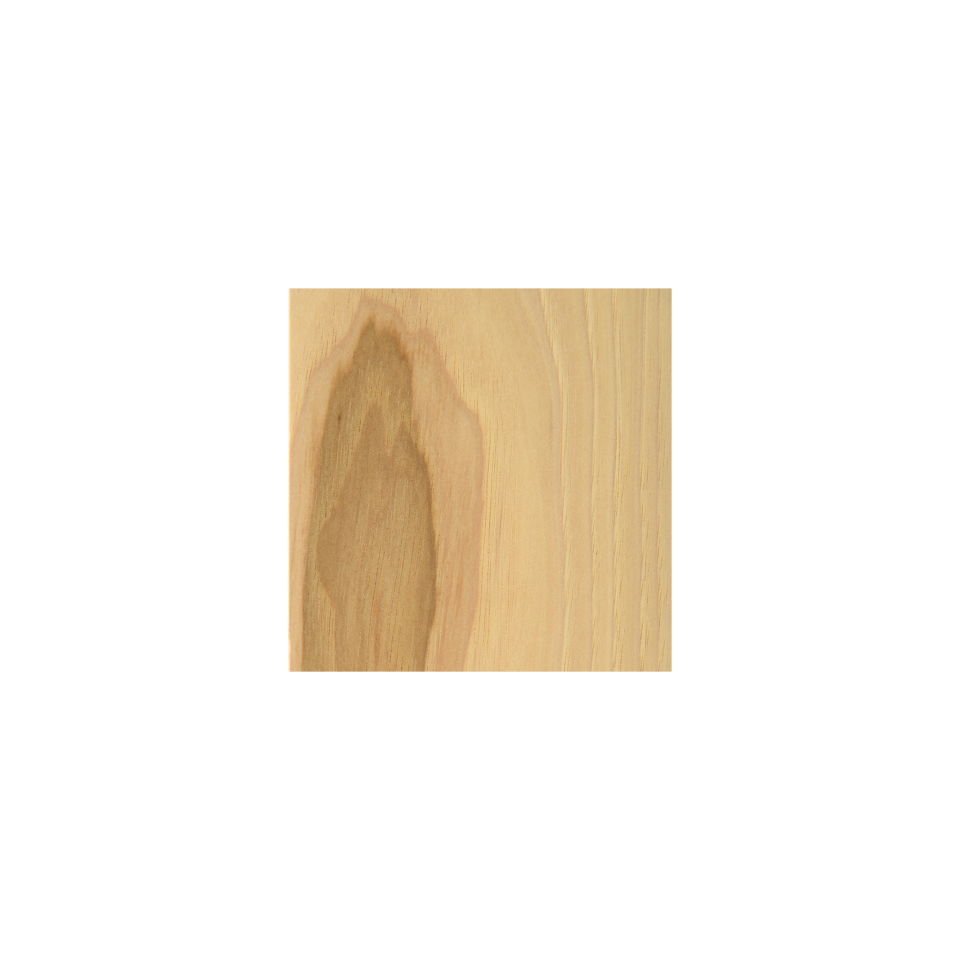

Hickory Wood Specie

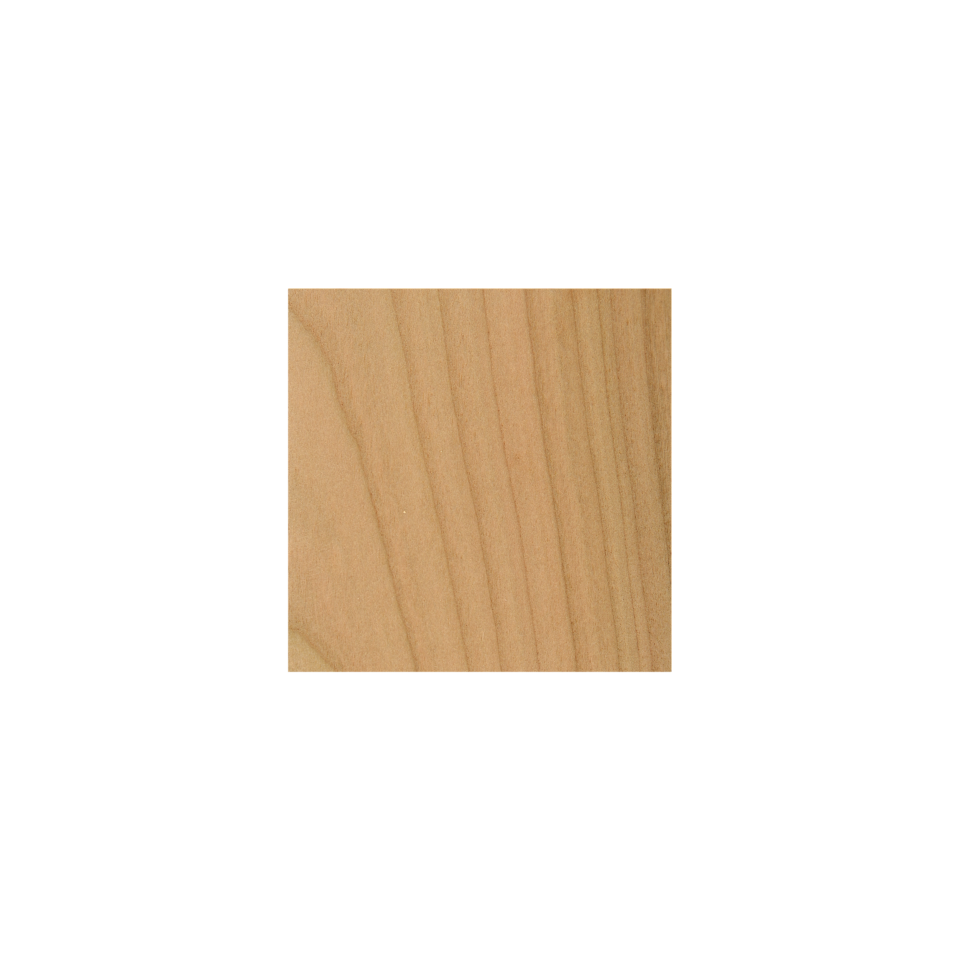

Cherry Wood Specie

Since its emergence from humble beginnings in New Haven, Kentucky, in 1955, Mouser Cabinetry has provided the highest quality custom cabinetry for over 65+ years. Today, located in central Kentucky, Mouser Cabinetry is marketed throughout the eastern two-thirds of the United States through an expanding network of authorized displaying Dealers.

Now, just as it was in the beginning, that same devotion to product quality and excellence has withstood the test of time to help create a product line for our customers that offers honest value and true quality. Every cabinet we manufacture is custom-crafted from the finest select woods, then is finished and protected with oven-cured catalyzed sealers and topcoat.

UnitedHealthcare and HealthSCOPE Benefits

Web Development By Cedar Hills Media & Marketing.